WELDING SHOP

BBM HM is equipped with a complete fabrication shop, starting from raw material processing, with a Messer CNC Gas Cutting Machine and A Band Saw, as well as a 2 PUC Gas Cut Machine for the execution of chamfers and bevel preparation.

For the Welding execution, Panasonic Make MMAW Welding Machines and TIG Welding Machines are available as well as Qualified Welders.

All the equipment is regularly maintained and calibrated, for quality and productivity purpose.

The NDT on the parts is executed by a Third Party Company, qualified for the Welding Quality Inspection as per the most stringent International Standards.

The maximum weight we can lift is 50Tons using EOT Cranes.

MACHINE SHOP

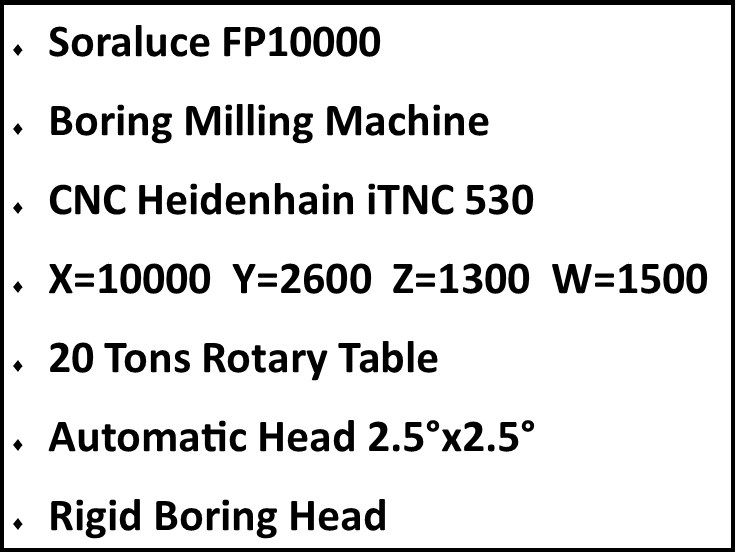

BBM HM Machine Shop is equipped with 2 Boring Milling Machine, Made in Europe, tailored with the latest technology to fit the customer needs.

Either 3 axis milling, tridimensional machining or heavy roughing operations, we can answer to customer needs quickly with the best solution, in cooperation and with the support of our Italian Mother Company.

The machines are continuously monitored and calibrated for the best accuracy and performances.

Preventive maintenance is performed on a regular basis to ensure ON TIME DELIVERY to our customer, one of our PRINCIPLES.

QUALITY DEPARTMENT

BBM HM regularly perform 100% Incoming Material and In-house Production Inspection prior to assembly.

3 inspector works full time on QC, totally independent from production.

A full range of Micrometers and Vernier is available on the Metrology Room, as well as a Portable 3D CMM Machine Faro ARM PRIME 8’ with an accuracy of 27 microns on 2.4 mts.

As soon as the inspection clearance is given, the material is segregated in an area, otherwise identified, awaiting the starting of assembly stage.

ASSEMBLY SHOP

Assembly is performed by a Team of Trained Fitters. If required, a Supervisor from Europe follows up directly on site to ensure the quality as per customer standard and expectations.

At the end of the assembly, a Hydraulic test bench and an Electrical test bench are available for Cold Testing as well as motor and spindle running test.

PACKAGING & DELIVERY

BBM HM can take care of the Packing and Delivery of the manufactured equipment Globally, including Custom Formalities. The Logistic Team of BBM HM can support the customer, for a hassle-free, turn-key supply.

We had lifted and Delivered overseas heavy consignments, managing boxes with weight up to 130 Tons.